Cellular concrete is an innovative, versatile, and highly insulating material, particularly suitable for the manufacture of prefabricated panels in three different versions:

The production of compact panels can occur either in a horizontal mold or in a battery mold.

The special composition of cellular concrete allows it to resist vertical shrinkage, even in molds up to 3 meters in height.

It is essential, during this process, to ensure proper curing of the product to achieve maximum strength and durability of the panel.

The surfaces of prefabricated cellular concrete panels have a compact and uniform appearance, very similar to traditional concrete; they can be customized with finishes such as washed gravel or white cement paste.

Mineral foam is a low-density material with high insulating power.

With a density ranging from 100 to 200 kg/m³ and thermal conductivity between λ= 0.045 – 0.065 W/mK, it is a valid alternative to less sustainable materials such as polystyrene and expanded polyurethane.

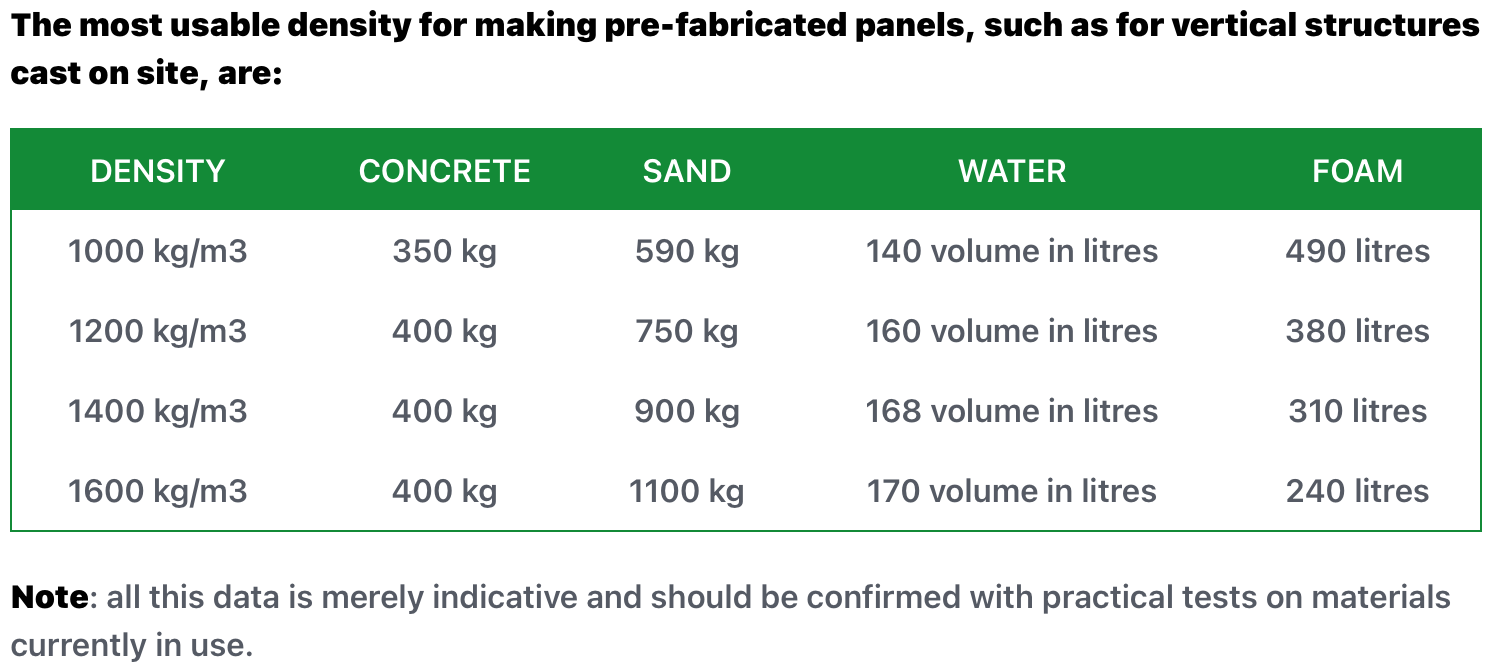

Le densità più utilizzate per la realizzazione di pannelli prefabbricati, come anche per le strutture verticali gettate in opera, sono:

Our specialized staff is at your disposal

Company specialized in solutions for cellular concrete production.

Via Amburgo 2 24040

Verdellino (BG) – Italia

Tel (+39) 035 4820680

Fax (+39) 035 4820680

[email protected]

© 2024 ISOLTECH Srl – C.F./P.Iva 01800190165